Modern Auto Recycling

Good for the Earth

Re-using quality parts from another vehicle is perhaps the purest form of recycling. Not only will you be preventing a mountain of waste from ending up in landfill, you’ll be reducing the need for new products to be manufactured. That saves energy and resources and reduces the harmful emissions that result from the manufacturing process.

The Ultimate Environmental Choice

It may not seem like a monumental choice to re-use good quality parts from another vehicle, but the resulting savings in energy, raw materials and pollution is astronomical.

By using Green Recycled Parts, you’ll be helping to sustain a modern global recycling industry that reclaims over 12 million vehicles across North America annually.

By using Green Recycled Parts, you’ll be helping to sustain a modern global recycling industry that reclaims over 12 million vehicles across North America annually.

Auto recycling is the ultimate environmental choice. No other product on earth is recycled more than an automobile. Not only does it keep a flood of dangerous toxins from being released into our ground and water, it prevents unnecessary use of valuable landfill. And by reducing the need for new parts to be manufactured, you’ll be preserving scarce natural resources and cutting down on the resulting pollution.

Fast Environmental Facts

- Over 80% of the entire vehicle by weight is reused, re-manufactured or recycled.

- Recycled parts save an estimated 80 million barrels of oil annually that would be required to produce new replacement parts.

- Auto recycling provides about 40% of the ferrous metal for the scrap processing industry across North America.

- Substituting low-sulphur scrap metal for high-sulphur raw ore can reduce a steel mill’s air pollution by as much as 86% and water pollution by 76%.

- The amount of toxic oils and fluids safely reclaimed by auto recyclers is equivalent to eight Exxon Valdez disasters every year!

The Green Recycled Parts Process

The modern auto recycling process is a model of environmental responsibility. Each vehicle goes through a methodical process designed to maximize the amount of material that can be reclaimed and to minimize the environmental impact.

Oil, gas and operating fluids pose a significant risk to the environment. Trained technicians carefully drain all the fluids and store them for reuse or recycling. Special equipment and methods are used in order to prevent any groundwater contamination. An average of 40 litres of fluids are removed from each vehicle and are used, re-used or responsibly disposed of.

The unusable portion of the vehicle is then crushed and sent to be shredded into fist-sized pieces for recovery. The valuable ferrous and non-ferrous metals are then separated and reused to make new cars and other products you buy… and the cycle starts again.

Each vehicle is inspected to determine which parts are appropriate for re-use. The VIN number and mileage of vehicle, along with the make, model and year are recorded in order to provide accurate inventory data.

Gas tanks, batteries and tires are all removed and are recycled, reused or disposed of appropriately.

The vehicle is then sent to the dismantling area where parts are removed, inspected and readied for resale. Each part is tagged, coded and entered into a computerized inventory system before it is properly stored.

What Happens to Your Car?

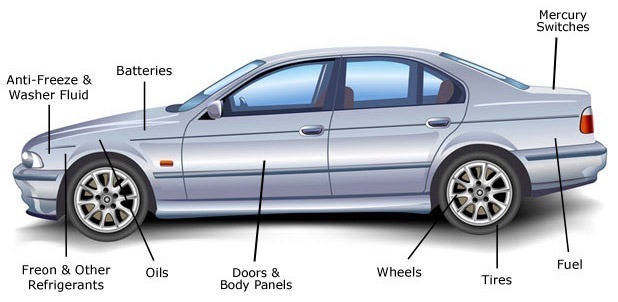

What happens with all the components? Take a look…

Anti-freeze & Washer Fluid

Fluids are separated and resold onsite or sent to reputable recycling facilities to be re-processed and re-used

Freon and Other Refrigerants

The gases from air-conditioning systems are carefully removed by licensed technicians to ensure none of them escape into the atmosphere. The used refrigerant is sold to a licensed buyer to be re-used.

Doors & Body Panels

Doors and body panels that are in suitable condition are sold to body shops to repair damaged vehicles. Unusable parts are reclaimed as scrap and the metal is recycled.

Tires

Quality tires with lots of tread life are sold for re-use. Other are sent to tire recyclers and processed as tire crumb to make new products or to pave our highways.

Batteries

After testing, batteries that are in good condition are sold to customers for re-use. Others are sent to a licensed recycling facility to be rebuilt.

Oils

Oil is drained from all vehicles, tested and re-used for energy recovery in licensed used oil furnaces to heat their buildings. Any excess is sent to recycling facilities to be re-processed and re-used.

Wheels

Wheels are sold for re-use. In some cases they are reconditioned. Damaged wheels are reclaimed as scrap metal.

Fuel

Using special equipment, gas tanks are punctured, drained and removed. The fuels are used by the auto recylcers in their own equipment or sold for re-use.

Mercury Swiches

For a period of time, manufacturers used mercury switches to control convenience lights and ABS systems. Although they are no longer being installed in new vehicles, there are hundreds of thousands of them still in vehicles on the road today. Switch Out is a national program designed to remove these switches from end-of-life vehicles and prevent the highly toxic heavy metal from being released into the environment.

ARC members have recovered thousands of them before they could do harm to our environment. Find out more about Switch Out.

Good for Your Wallet

You’ll significantly reduce your vehicle repair cost without sacrificing quality when you make the switch to recycled green parts. In fact, road-tested and guaranteed green parts are generally about half the price of new OEM replacement parts.

Same Quality, Way Lower Price

You’ll significantly reduce your repair cost without sacrificing quality when you make the switch. In fact, Green Recycled Parts are generally about half the price of new OEM replacement parts.

When Your Car’s on the Hoist, Remember You Have a Choice

There’s a bit of a misperception out there we’d like to clear up. You don’t need to be a do-it-yourselfer to use recycled parts. In fact, our biggest customers are repair shops just like yours. So the next time you bring your vehicle in, ask your mechanic if the Green Recycled Parts option is right for your repair. You’ll save yourself about half the price on parts… and be doing something amazing for the environment in the process.

Good for Your Vehicle

You can rest assured that the recycled parts you purchase will be right for your vehicle because they’re the original OEM parts made for your vehicle — the original specifications, the perfect fit, the right performance.

Original Parts at a Fraction of the Price

At roughly half the cost of new parts, Green Recycled Parts are the original and genuine parts made to original manufacturer’s specifications. They’re road tested and guaranteed to fit your vehicle. From late model components to obsolete or hard to find parts you can be sure that your Green Recycled Parts will perform to the standards to which they were designed.

Quality Tested

ARC auto recyclers ensure the quality and reliability of the parts they sell. During the dismantling process, every part is inspected and tested so only those that meet strict guidelines and tolerances are offered for resale. Some parts such as engines and transmissions may be remanufactured while other parts such as lights and wheels may be reconditioned.

Parts that need to be protected from the elements are carefully stored in warehouses to preserve their integrity and performance.

As parts are inventoried, the model year and mileage of the vehicle they came from are recorded to provide information about the condition of the part you’re purchasing.

ARC members guarantee the part you purchase will be in working condition or they’ll exchange it. Some offer longer warranties and even make optional extended warranties available. Feel free to ask when you’re purchasing your Green Part.

Available at Your Fingertips

Modern auto recyclers make it simple, fast and painless to source and order the exact Green Part that’s right for your vehicle.

When each component is dismantled for re-use, it is assigned an industry-wide interchange number that identifies which vehicle, model and type it fits. Additional information is recorded, grading the condition of the part based on mileage, minor damage, and other details. The part is then tagged with a bar code or inventory number, and then entered into a computerized inventory management system. With the click of a mouse, recyclers know what they have in stock and where it’s warehoused so they can locate it in seconds.

ARC members have adopted a sophisticated parts locator network that connects the inventory data of hundreds of auto recyclers across the province. Using the parts interchange numbers, anyone can go on-line and locate the right Green Part for any vehicle in seconds.

Automotive Recyclers of Canada

The Automotive Recyclers of Canada is committed to the maintaining the highest standards of environmental stewardship and business ethics among our members.

Progressive Auto Recycling

Forget the old “junk yard dog” image of the auto recycler. Using modern business practices and strict environmental controls, today’s recyclers provide low cost, high quality used auto parts in a way that benefits the consumer, the industry and the earth. In doing so, they help to reduce insurance rates, vehicle repair bills and staggering amounts of pollution.

Recyclers purchase end-of-life and accidented vehicles, and ensure that all vehicles are retired in an environmentally sound manner. They spend significant resources to build and maintain facilities specially designed to capture and store harmful materials, keeping them from contaminating soil and groundwater.

Today more than ever, auto recycling is paying economic and environmental dividends around the globe.

Contact ARC

134 Langarth Street East

London, ON N6C 1Z5